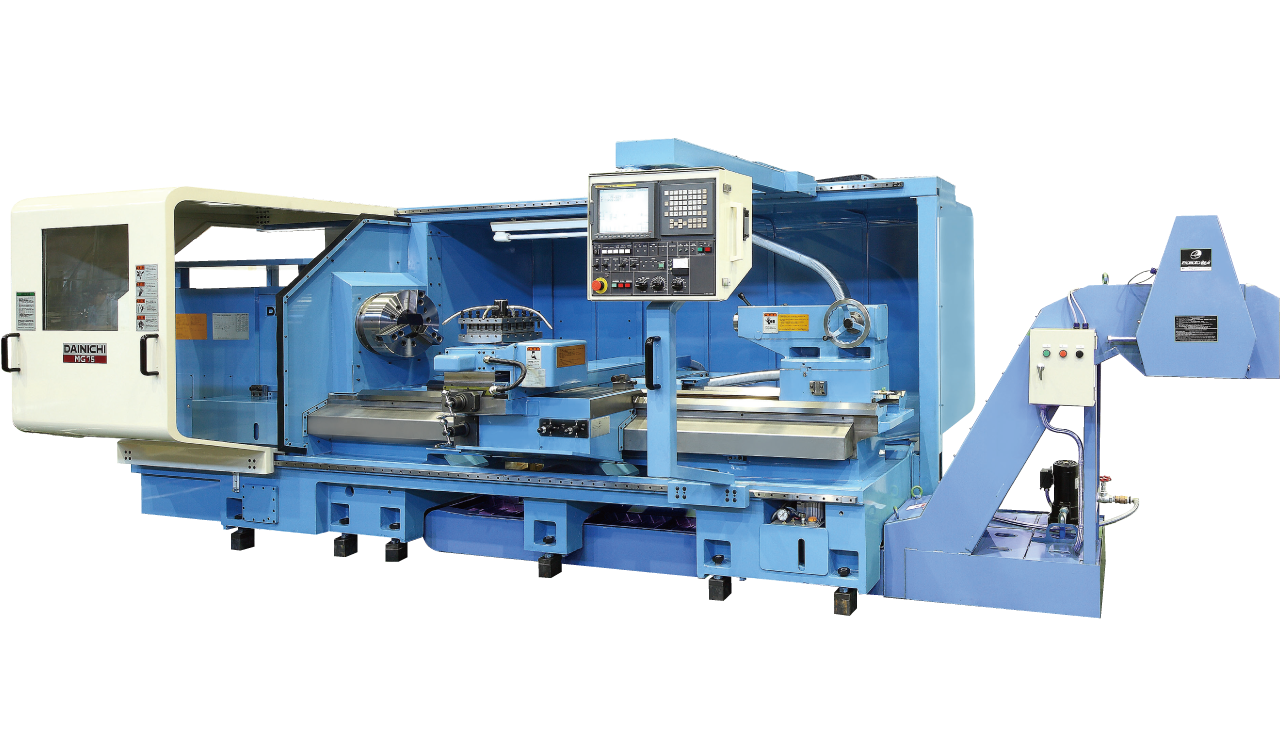

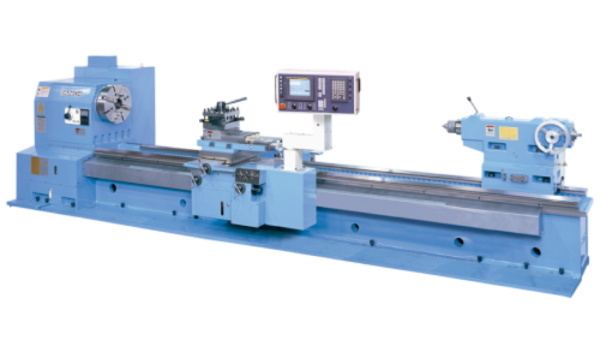

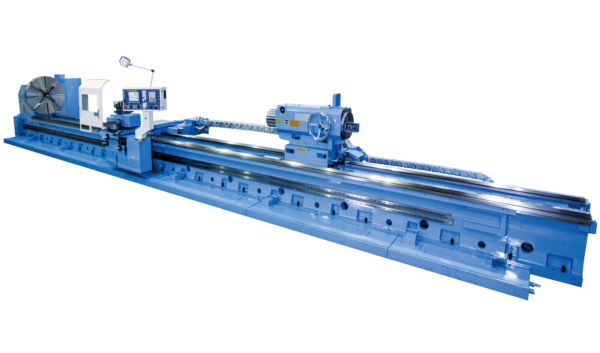

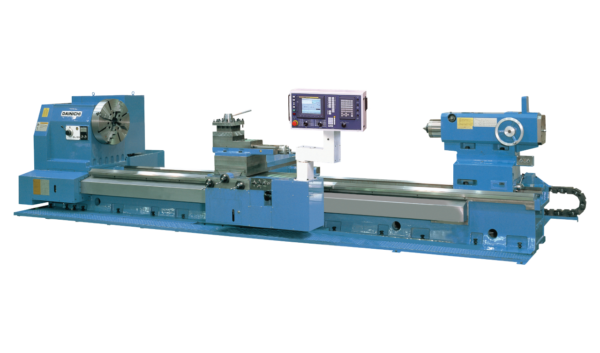

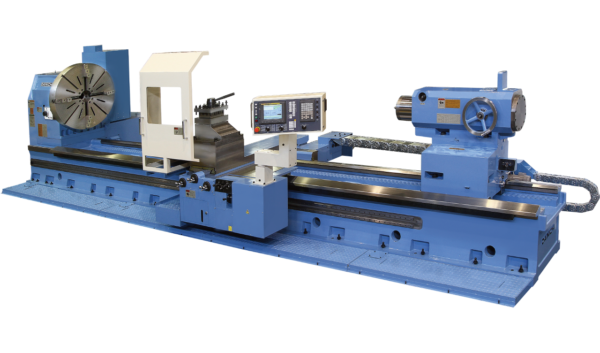

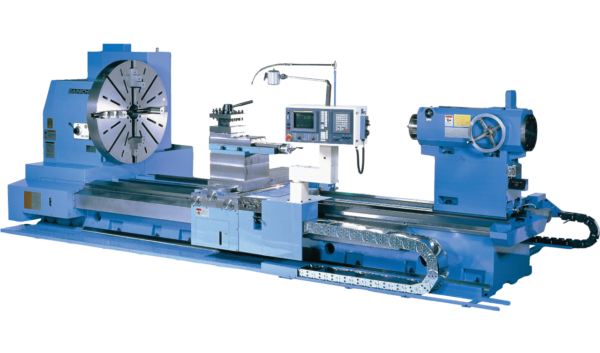

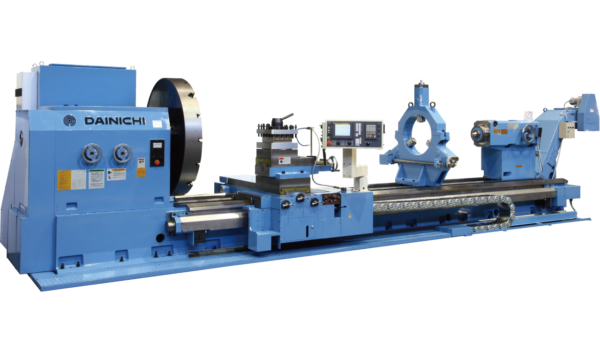

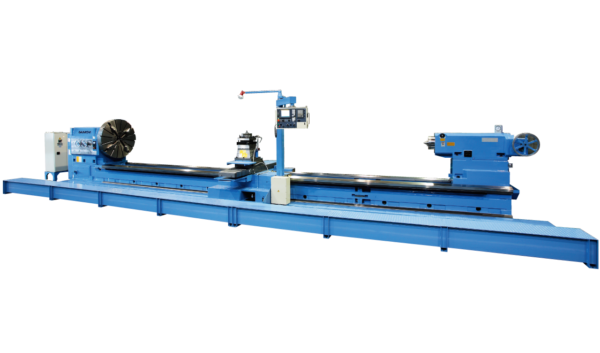

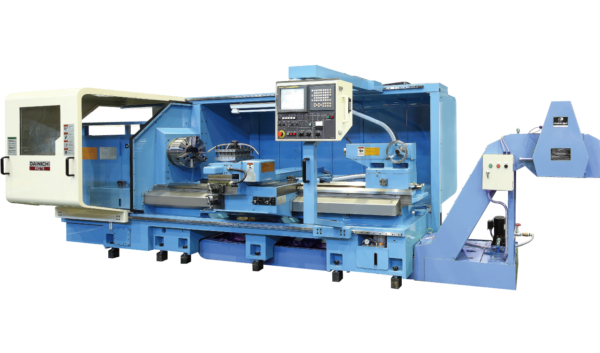

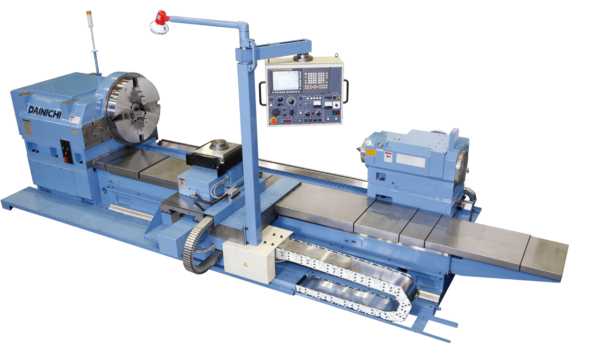

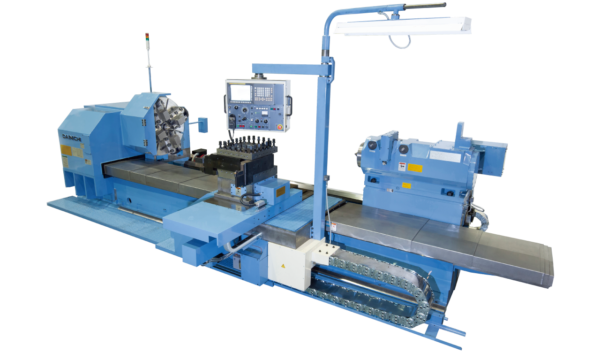

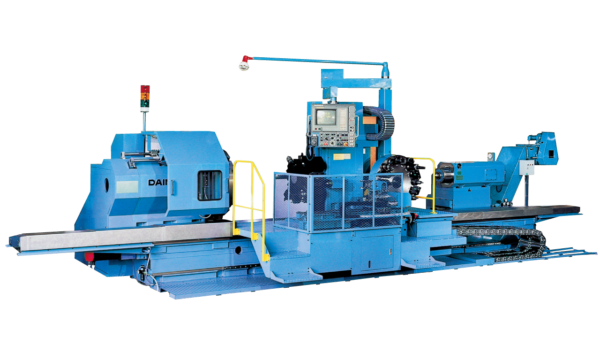

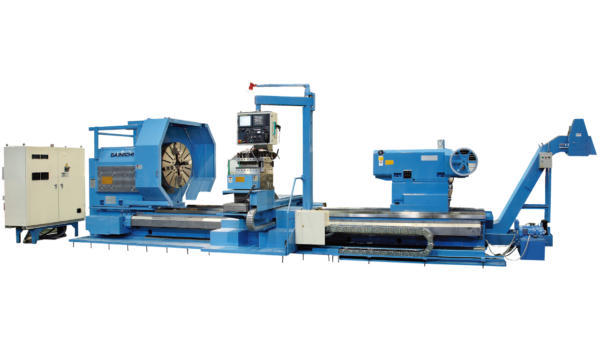

High performance CNC lathe

Offering flexible performance only found with a manual handle. Twin turret designs offering further flexibility!

A highly productive mobile-type CNC lathe with 25 distinct features.

- Automatic main shaft speed shifting (3 groups hydraulic type)

- Includes an operation cover, front surface cover can also be applied (option, available up to the 200 series)

- Mechanically and electrically integrated design

- Wide ranging spindle speed (3–1,800min-1)

- Constant surface speed control also possible in manual mode

- 12″ hydraulic chuck equipped as standard

- Horizontal-type automatic four-station cutter holder equipped as standard (easily replaced by a horizontal six-station cutter holder or an eight-station drum-type cutter holder)

- V8-type facing cutter holder (option)

- Thick tailstock spindle (100 mm in diameter) providing a maximum thrust of 10,200 N, with a center-to-center support weight of 1,600 kg

- Left-right movable pendant (capable of oscillating 90°)

- Playback feature enabling the creation of programs that memorize test cutting data to be recalled at a later point (option)

- 3-stage handle feeding (0.001/0.01/0.1 mm per pulse)

- Rear surface cover

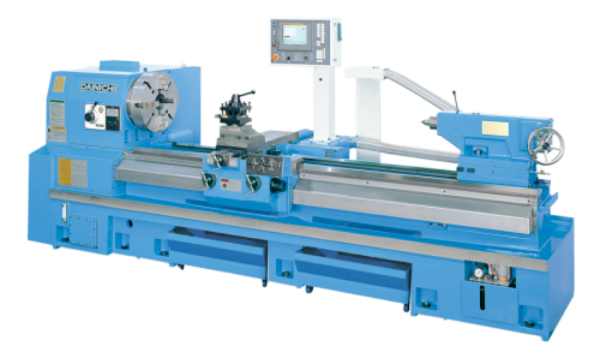

- Hydraulic tailstock spindle (manual tailstock spindle like that shown in the photo on the right also available)

- Chip conveyors (option) in the form of a below bed conveyor enabling greater chip sweeping, or a rear bed conveyor that reduces the service area required

- Uses an AC spindle motor that does not require maintenance

- Uses high performance, high precision ball screws

- Offers a wide bed (480 mm), a symmetrical V-shaped carriage sliding surface that is resistant to meandering, and a bed/leg integrated cast metal structure

- Provides an X/Z-axis manual handle that allows for operation while observing the cutting edge

- Inch and millimeter-length screw cutting is a simple process that can be performed through single fixed cycle or manual handle cutting, or a combination of both.

- Feed on/off switch in manual mode (enabling the same feed amounts as a general-purpose machine each time)

- Foot switch for moving the tailstock spindle that allows jog feeding

- Main spindle monolever startup switch in manual mode

- Convenient air floating device for moving the tailstock

- Manual guide i with proprietary DAINICHI materials files and tooling files